Manufacturers that changed history - Van's Aircraft

In the early 1970s, a skinny young engineer from a small town in Oregon built himself a better mousetrap. Actually, it was a better airplane.

After improving another homebuilt design, the Stits Playboy, as much as he could, Richard (Van) Van Grunsven decided to start with a clean sheet of paper. His RV-3 impressed a lot of people ("RV" of course, stands for Richard Van Grunsven). Many of them were willing to take on the task of building an airplane from scratch so that they, too, could have an airplane that flew like Van's. Already an experienced pilot, Van quit his job with a forklift company and seized the opportunity to work with his real love, aviation. He founded Van's Aircraft, Inc. in 1972 and began selling plans and a few parts for the RV-3. These he manufactured himself, working in a small shop behind his house in the small town of Reedville, Oregon. As business grew and Van's Aircraft began producing full aircraft kits and new designs, the company moved to larger quarters in North Plains, Oregon, a small town about 25 miles west of Portland. Van and his wife Diane built a home on a residential airpark just across the road from the factory. For many years, the RV prototypes and demonstration aircraft flew from the grass runway at the airpark.

Eventually, after several expansions, Van's had exhausted the available opportunities in North Plains, so in 2000 the company moved to a new 60,000 square foot facility near the small town of Aurora, Oregon (the people at Van's just like small towns.) Now based on the Aurora State airport (KUAO), the employee-owned company currently employs over 50 people (and dozens more in sub-contract roles) and keeps them busy manufacturing several hundred complete aircraft kits a year. In an era of out-sourcing and foreign manufacture Van's is a bit of a rarity - a huge majority of the components used in the RV aircraft are manufactured in the USA, most of them in Van's factory.

Van continues to reside in North Plains, but commutes to Aurora by air, flying whatever RV strikes his fancy on the day. Van's Aircraft became employee-owned several years ago and the day-to-day running of the company is now handled by others. After years of working extremely long hours, Van has carved out a little more time for himself. A lot of it he spends flying sailplanes. At this, he has become quite expert, often winning his class (or at least placing quite well) in large soaring meets. When he is not in the cockpit of his Antares, he and Diane travels, explore the world and visit their three children. In recent years, he has become passionate about youth build projects, helping to introduce young people to aviation and introducing them to their own potential by building airplanes.

RV-7

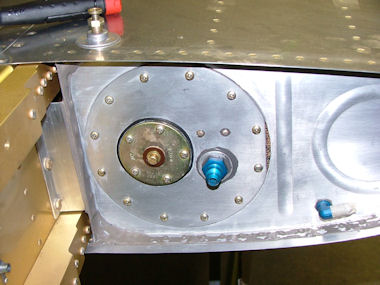

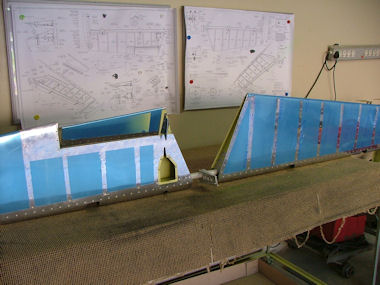

RV Aircraft are low-wing monoplanes of traditional aluminum construction. They use simple steel rod or leaf fixed landing gear. Aileron and elevators are controlled by a between-the-knees stick driving the surfaces through pushrods and ball bearings. The rudder is controlled by stainless steel cables. Fuel is contained in two sealed, removable, portions of the leading edge, and routed through a selector valve in the cockpit to the engine driven fuel pump. An electric fuel pump is installed in the system as a backup.

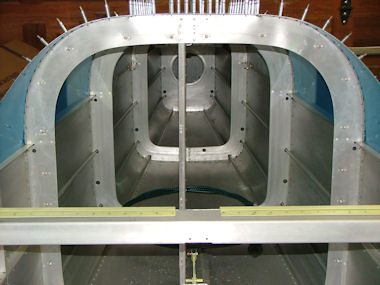

RV structures are "monocoque" or "stressed skin" designs. This means that the skins provide much of the airframe's strength. The primary bending loads of the wing are carried by the single main spar. Wing torsional and drag loads are carried by the wing skins and rear spar. The same is true of the tail surfaces. The fuselage skins, whose shape is maintained by formed aluminum bulkheads, provide torsional and bending strength. Aluminum angle longerons in the fuselage provide stiffening for the skin and greater strength at localized points of attachment.

The RV-4 and RV-8/8A are soloed from the front seat, but elevator and aileron controls for the rear seat are also provided. The RV-7/7A, RV-9/9A and feature full dual controls, except passenger brakes, which are optional. Baggage space in the RV-4 consists of about 7 cubic feet in a compartment behind the hinged seat back. Weight allowed is about 35 pounds, depending on optional equipment and other loading factors. The RV-4 has an optional front baggage area, accessible from within the cockpit, that can carry up to 15 pounds. The wide forward fuselage of the RV-8/8A provides not only more instrument panel space, cabin width and foot room than the RV-4, but also allows a forward baggage compartment between the instrument panel and the firewall. It holds about 4.75 cubic feet, and is accessible through an outside door. The traditional baggage compartment behind the rear seat remains. By having two places for baggage, one forward and one aft, the pilot has more loading options and is better able to control the CG. The RV-7/7A and RV-9/9A carry baggage behind the seats in a large 12-14 cubic foot bay. Depending on various factors (mostly the engine and propeller up front) they can carry between 65 and 100 pounds of baggage and two adults. The RV-10 has a generous baggage compartment aft of the rear seats, reached through a baggage door on the left side. The rear seats can be removed in a minute or two, providing a truly huge space.

RV-7

All RV wings are relatively low aspect ratio, constant chord designs with no taper or twist. This planform offers light weight, easy construction, and favorable stall characteristics. The wide chord maximizes the permissible CG range. It also provides generous wing area and low wing loading even in a wing of short span. Because of this low wing loading, climb and altitude performance are unusually good for an airplane of such short span. Two-seat RVs (the RV-9/9A excepted) use the proven NACA 230 series airfoil. These are turbulent flow airfoils with very low pitching moments. They do not require perfectly smooth surfaces to achieve good performance, so they remain almost unaffected by bugs and rain. The low pitching moment allows cruise trim drag to be kept to a minimum. The RV-9/9A uses a new Roncz airfoil design with a slightly longer wing span, shorter chord and slotted flaps for better low speed performance. The RV-10 uses a similar wing, but with a slightly different airfoil.

RV-9

The most important part of the airplane is the people inside it. Their safety is paramount. Since forward visibility and safety are close relatives, upright rather than supine seating was chosen. We felt that it would be illogical to lay the passengers down and then have them try to see forward over the engine. Operational safety and crash survivability, often overlooked in homebuilts, are primary concerns to everyone at Van's. First, to limit the possibility of accidents, RVs have excellent controllability, gentle stall characteristics, and superb visibility. In the event of an unavoidable crash landing, (engine failure over rough terrain, for instance) their low landing speed has been a real lifesaver. A crash at 50 mph is 70% more survivable than one at 65 mph. This, along with the rugged cockpit structure and sturdy roll bar should permit you to walk away from, or at least survive, almost any controlled landing.

RV-6

Comfort is also important. Too many airplanes contort their occupants to suit their shape. We choose to provide generous legroom, shoulder room and head room first and design the airplane around them. RV cockpits are quite roomy and accommodate pilots and passengers up to 6' 4'' tall -- even taller in the RV-8/8A. Minor modifications are possible to allow even taller people to fit.

RV-8

Easy maintenance was another prime consideration. Controls, linkages and fittings are easy to install and service. Removing everything necessary for a complete annual inspection (cowl, inspection covers, fairings, etc.) takes less than an hour. The straightforward, simple airframe, control system and landing gear have only a few points that require service. Given proper storage and maintenance, the airframe is essentially a "life-time" structure.

RVs are designed and built so they can be dismantled when necessary. All of the tail surfaces removable. Wings are constructed in two separate panels and simply bolt to the fuselage. The landing gear attaches with just a few bolts. This permits easy transport to the airport for initial assembly, or later disassembly for major maintenance. Disassembly does require disconnecting the control, electric and fuel systems, so RVs should not be thought of as "take-home" or "trailerable" airplanes.

In the early days, Van coined the term "Total Performance" to describe his design goals. In thirty years, we haven't come up with a better description. While the RVs are excellent cross-country airplanes, they are not simply "go-fast" machines. They have outstanding low speed characteristics and short-field capabilities; a rare combination. Most are capable of delightful sport aerobatics.

Balancing all the competing and conflicting requirements involved in a "Total Performance" airplane is a difficult task - just think of how few airplanes have really done it well. RVs are those airplanes.

By the end of 2012, about 8000 RV kits have been completed and flown, and thousands more are under construction. Completion rates currently average about 1.5 per day. RVs are flying in at least 45 different countries and kits have shipped to about sixty. From a small farm in Oregon, these wonderful airplanes have achieved a global following. Not because of any superior marketing campaign, but simply because they fly so well and bring so much pleasure to their builders.

As the company celebrates its 40th anniversary year, Van's Aircraft is solvent, strong and alive with new ideas. The coming years will present plenty of challenges but they intend to meet them the way Dick Van Grunsven did when building the company: with honesty, practicality, diligence and imagination.

|

|