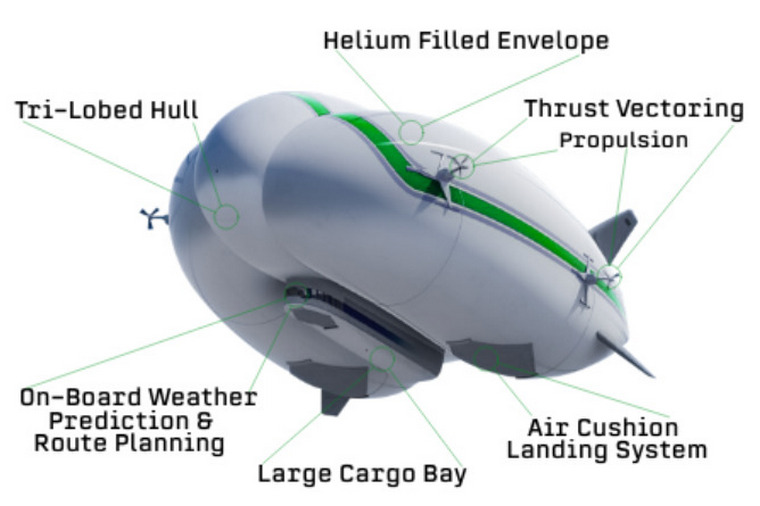

Midweek Update 25 May 2023Google Banner Ad THIS WEEK IN MIDWEEK UPDATE Farewell AFB Swartkop, hello Air Force Mobile Deployment Wing. Sonex first flights: Paul Dye flies his electric Xenos. Value for money not up to scratch for SANDF prime mission equipment investment - JSCD. Paramount and Greece partner on N-Raven loitering munition production. United Aviate Academy chooses Diamond Aircraft DA42-VI for multi engine training. Gripen E production line inaugurated in Brazil. Austro Engine is researching future propulsion systems. Embraer and NetJets announce deal for up to 250 Praetor 500 jets in excess of US $5 billion. Introducing the Z1 hybrid airship. Worldwide incidents and accidents - USA Crash Following In-Flight Fire Fresh Air, Inc. Convair This week in History - Lieutenant Commander Charles Samson becomes the first person to fly an aircraft off the deck of a moving ship. Bonus Video - Van's RV 10 Brakpan to East London      27 Klipriver Fly in. Contact Michael 083 662 4564 25 to 28 SAPFA Presidents' Trophy Air Race Middleburg airfield Website: www.sapfa   1 & 2 Drones and Unmanned Aviation Conference Birchwood Hotel. Contact Gerald E-mail: admin@bussynetadt.co.za Cell: 067 611 0365 or Byron E-mail: byron@bussynetadt.co.za Cell: 067 611 0365 1 to 4 RC Extravaganza at Henley Model airfield. Contact Emil Henrico E-mail: info@rcasa.org.za Cell: 082 962 2334 3 Kroon Fly In. Contact Marius 083 419 6613 or Kevin 061 008 9561 3 EAA Chapter 322 breakfast gathering 07h30 EAA Auditorium Rand Airport. Contact Neil Bowden E-mail: airadventuresa@gmail.com 3 Parys Airshow. Contact Brendan Horan E-mail: brendan@creativespacemedia.co.za 10 EAA Young Eagles Day (Venue TBA) & EAA International Young Eagles Day. Contact Neil Bowden E-mail: airadventuresa@gmail.com 10 Newcastle Airshow. Contact Johan Pieters E-mail: johan@champ.co.za 9 to 11 EAA Convention. Middelburg Airfield. Rsvp@eaa.org.za 9 to 11 The Sling Winter Weekend Away Midlands Meander. Regret Sling Aircraft Only. Bookings close 23 May. Contact Shanelle Visagie Shanelle@Slingaircraft.com 11 Brakpan Aero Club Cobra Club and fly-in. Contact Clarissa E-mail: Clarissa@airborneaviation.co.za Cell: 074 113 2911 15 Virginia Airport Air Show, Durban. Brendan Horan E-mail: brendan@creativespacemedia.co.za 16 SAC Fundraiser event venue TBA. Contact Annie Boon E-mail: info@anniesaviationcorner.com 17 Maputo International Airshow on the waterfront. Contact Gavin Neil E-mail: gavin@haps.co.mz Cell: +258 84 391 7408 30 June to 2 July EAA Taildraggers at Warmbaths airfield (Bela Bela). Contact Richard Nicholson E-mail: ichard.nicholson1963@gmail   FAREWELL AFB SWARTKOP, HELLO AIR FORCE MOBILE DEPLOYMENT WING Kim Helfrich www.defenceweb.co.za It probably went completely unnoticed by the thousands who thronged the oldest base in the SA Air Force (SAAF) earlier this month for the SAAF Museum air show - that Air Force Base (AFB) Swartkop is no more. They were on, according to advertising for the air show, the "Mobile Deployment Wing, formerly AFB Swartkop".  What used to be Snake Valley on its eastern side where the mobile air deployment wing is based as well as the old gymnasium opposite the main entrance on the Old Johannesburg Road is another base component. The SAAF Memorial is on Bays Hill, immediately north of the main runway, also on Swartkop land. Wingrin's Unoffical SAAF Website has it Swartkop started life as Air Force Station (AFS) Zwartkop in April 1921. It is the oldest surviving and still operational base in the SAAF. "The base was reproclaimed an air force station on 1 March 1999. The SAAF commenced vacating the base in 1999 with the intention of leaving only the SAAF Museum and the base becoming 'Zwartkop', an extension of AFB Waterkloof. The SAA Historic Flight moved to the airfield and the airfield has been proclaimed a heritage site. "The SAAF then changed its mind and decided not to relocate its operational units," reads the historical overview from Wingrin's informative site.  SAAF Museum management was not prepared to comment on the disappearance of AFB Swartkop from its promotional material referring this publication to "higher authority". Two months later, no response from the SA National Defence Force's Directorate Corporate Communication has been forthcoming. .jpg) FIRST FLIGHTS: PAUL DYE FLIES HIS ELECTRIC XENOS  Congratulations to Paul Dye and Louise Hose of Kitplanes Magazine who flew their eXenos (S/N X0061) with Zaero Elecric Propulsion for the first time today! The aircraft uses the Zaero Electric Propulsion system pioneered by Gabriel DeVault and supported by both Sonex and DeVault. Paul made two flights today from his home airpark in Dayton, Nevada. The stars finally aligned with the weather (and schedules) in western Nevada on the morning of 8 April and the Dye/Hose eXenos took to the air for its first and second flights from Dayton Valley Airpark. Paul Dye flew both flights using the EAA Test Card #2 (suitably modified for an electric powerplant) and found the airplane to fly fine, with only a slightly heavy left wing and a stall speed right on the book value of 38 knots. The electric power system devised by Gabe DeVault worked flawlessly and Paul was able to manage temperatures of the motor, controller and battery to complete all the flight test objectives on the card. While the motor warms up quickly during take-off and initial climb, the temperature are easily managed while maintaining a respectable positive rate of climb to pattern altitude.  VALUE FOR MONEY NOT UP TO SCRATCH FOR SANDF PRIME MISSION EQUIPMENT INVESTMENT - JSCD www.defenceweb.co.za This conclusion was drawn by the JSCD following presentations by Armscor, Denel and the SANDF into what a Parliamentary Communication Services statement termed the "satisfaction levels" experienced regarding PME serviceability and mission readiness.  The JSCD acknowledged an increase from 6.45% to 38.10% in delivered capital and technology contracts and wants it sustained to ensure PME is ready for deployment going ahead. "Nonetheless, the committee is concerned that operational readiness of PME remains largely unserviceable. Additionally, the committee is alarmed to hear the majority of contracts given to Denel Aeronautics were satisfactory, according to the SANDF, the reality is that a majority of the aircrafts remain grounded and Denel has resorted to cannibalising parts to service aircrafts needed for mission deployment (sic)." "This situation," the statement has it, "leads the committee to question the financing model currently utilised and the value for money the SANDF is getting". Kobus Marais, Democratic Alliance shadow defence minister, told the JSCD that just six of the SA Air Force's 36 Oryx helicopters are operational compared to 17 last year, and only two Rooivalks are operational out of a fleet of 11. This is largely because Denel Aeronautics is unable to service them.  - Copy.jpg) "At the rate at which things are deteriorating, next year we will not have a single Oryx helicopter working," Xaba warned, and said Parliament needs to find a better way to equip the SANDF and hold Denel accountable. "The committee acknowledges that the delivery of contracts might be system specific and not holistic in getting the aircrafts airborne, it nonetheless underscored the need for general solutions in getting PME ready. It urged the department to utilise specifically allocated funding efficiently and effectively to enhance the performance of strategic mission equipment (sic)," the JSCD said in its statement. SANDF Chief of staff, General Michael Mantswana, told the JSCD on 11 May that Denel only met 53% of the prime mission equipment orders from the SANDF over the past year. Out of 104 active contracts and orders for equipment totalling R21.9 billion, Denel has fully delivered on 45 orders and received R11.7 billion in payments for the operational and capital equipment. More than R10 billion in orders is still outstanding, mostly covering maintenance and support. Denel Land Systems has R8.8 billion in outstanding orders, mostly relating to the Badger infantry fighting vehicle for the SA Army. The presentation to the JSCD last week followed a 27 March meeting between the Military Command Council and Armscor and Denel to discuss Denel's turnaround strategy and the support it can provide to the SANDF. This was followed by a Military Command Council visit to Denel plants on 3 and 4 April, and on 12 May, 200 senior members of the SANDF visited Denel facilities to see how the company was restarting production following the arrival of bailout money for the struggling state-owned company. The Defence Materiel Division of the SANDF warned that Denel's performance may not drastically improve soon. "The impact of the new Denel turnaround strategy is not yet felt in the readiness levels of the DoD's PME." It also warned that "the country can no longer afford to lose the remainder of the skills sets vested within the employees at Denel. Employees with scarce skills that form part of the manufacturing of arms for the SANDF should as far as possible be retained."  The SANDF acknowledged that in spite of Denel's troubles, "the underfunding of the SANDF does contribute to the situation in which the Defence Force finds itself in." Defence expert and Director at African Defence Review, Darren Olivier, believes "it's difficult to overstate how serious this situation is. Defence capabilities are not just shrinking, they're collapsing and at risk of being lost entirely. We've been warning about this for years, as have the DoD's senior staff and the 2015 Defence Review. It was all ignored."  www.defenceweb.co.za  Greek state-owned company Hellenic Defence Systems is partnering with global aerospace and technology company Paramount to produce the N-Raven long range loitering munition as the Irix. The loitering munition system is called Irix after the word used by Greek poet Homer to describe hawks, and is poised to make history as the first loitering munition produced in Greece, Paramount said in a statement. The agreement provides for the manufacture of internationally competitive long range loitering munitions in Greece, for the Greek market as well as export to international customers. Leading Greek state-owned company, Hellenic Defence Systems (EAS), is a strategic partner to some of the largest companies in the international defence industry, with a 140 year-strong tradition of designing, developing, manufacturing and supplying the Hellenic Armed Forces with NATO-type defence systems. The Hellenic Ministry of Finance is the main shareholder and the company is supervised by the Ministry of National Defence. Nikolaos Kostopoulos, EAS Chief Executive Officer said, "We are excited to be going into production - in Greece - with one of the world's most advanced long range loitering munitions. In Paramount we found an ideal strategic partner, recognised as a pioneer in loitering munitions". "EAS and Paramount jointly developed an innovative and advanced product, specifically for the Greek market, called Irix. This is a lighthouse project for the redevelopment and enhancement of the Greek defence industry, which we are immensely proud of." IRIX is based on Paramount's N-Raven unmanned aerial vehicle (UAV) technology. The N-Raven is digitally designed with quick technology transfer in mind to enable government manufacture of loitering munitions technologies in own countries. The partnership includes technology and skills transfer for local co-production of Irix as well as EAS' ongoing participation in continued research and development (R&D) of future Irix system upgrades.  Commenting on the venture, Steve Griessel, Paramount Global Chief Executive said: "We are privileged to be one of EAS's global partners of choice, leveraging decades of unmanned aerial innovation and portable production expertise to jointly develop and produce Irix in Greece. At Paramount we believe true partnerships and innovation mean we design and produce technologically advanced, affordable and customisable solutions with our partners." The companies also announced involvement of other Greek companies in the supply chain for production of the system will be encouraged. This will see greater participation of and autonomy for the Greek defence industry. IRIX, according to Paramount, is a robust yet cost effective unmanned aerial vehicle (UAV) and loitering munition system, designed to strengthen armed forces' aerial reconnaissance, engagement and precision strike proficiencies, addressing modern requirements for asymmetrical and symmetrical warfare operational capability. The platform offers operational commanders real time actionable intelligence and from it, an ability to strike high-value targets deep in enemy territory or deny enemy use of operationally essential terrain. Paramount Industries Greece Chief Executive George Kyriakos said: "The role of loitering munitions on the modern battlefield has steadily increased, as seen in recent conflicts all around the world. The socio-economic ramifications made ensuring security of supply of any nation's defence technologies and capabilities a prerequisite to stability and growth". "The partnership between Paramount Industries Greece and Hellenic Defence Systems will provide a powerful solution to the growing need for advanced and precise loitering munitions, enhancing Greek as well as NATO and European defence capabilities. Importantly, it will boost our local industry creating high tech opportunities and skilled jobs in the local market," according to Kyriakos.   Diamond Aircraft proudly announces a new strategic partnership with the United Aviate Academy in Goodyear, Arizona, by ordering 5 new jet-fuel powered DA42-VI twins. The firm order will see the first delivery take place at this year's Sun 'n Fun Expo in Lakeland, Florida, with the balance of the new fleet being delivered by the end of Q2 2023. "We are excited to incorporate the DA42-VI Diamond Aircraft as our multi-engine trainer to our growing fleet. With its advance aircraft systems and performance, the DA42-VI provides us the unique opportunity to prepare our pilots for the next step in their career while honouring our commitment to using the most sophisticated training aircraft on the market today." Dana Donati, CEO United Aviate Academy. Trevor Mustard, head of sales and marketing, Diamond Aircraft Canada, noted, "We are very pleased to have partnered with United Aviate as they continue to grow. Their mission to provide world-class flight training through equal opportunity initiatives will further incentivize a broader spectrum of student pilots and help meet the demand at the airline level. Diamond is proud to be part of United Aviate's new endeavour as it trains the pilots of tomorrow with the safest, most sustainable twins on the market today". The 4-seat DA42-VI is the most recent version of Diamond's technologically advanced piston twin, the first certified general aviation aircraft to combine a modern airframe, avionics, and power plants. Well over 1,100 DA42's has been delivered since its introduction, outselling all other certified piston twins combined. The all-composite DA42-VIs are equipped with efficient, clean and reliable 168 hp jet fuel AUSTRO engines AE300, Garmin G1000 NXi with 3-axis Automatic Flight Control System and optional electrically powered air conditioning. The DA42-VI is an excellent platform for Multi-Engine-Piston (MEP) training. With its unique combination of performance and utility, the jet fuel powered aircraft is designed to make transitioning from a single engine to a twin much easier. The aircraft generates fuel savings of up to 50% compared to conventional AVGAS powered twins and its panoramic canopy provides excellent visibility during all flight manoeuvres.   Embraer and Saab today have inaugurated the production line of the Gripen E in Brazil, at Embraer´s plant in Gavião Peixoto (São Paulo State). This is an important milestone in the technology transfer program and the companies' commitment to work together on new business opportunities. The event was attended by the President of Brazil, Luiz Inácio Lula da Silva, the Minister of Defense, José Mucio Monteiro Filho, and the Brazilian Air Force Commander, Lieutenant-Brigadier Marcelo Kanitz Damasceno, among other important civil and military authorities. and representatives of different sectors of Brazilian society. The inauguration of the final assembly line, which is the only one for Gripen E outside of Sweden, marks the delivery of one the most significant contributions to the Gripen fighter ecosystem in Brazil. The Embraer plant in Gavião Peixoto with the Gripen Design and Development Network (GDDN), the Gripen Flight Test Centre (GFTC), and now the assembly line, is home to the development, production, and testing stages of the aircraft. Since the signing of the contract to supply 36 fighters - Gripen E (single seater) and eight Gripen F (twin seater) - to the Brazilian Air Force in 2014, Embraer and Saab have been working together on the largest ongoing technology transfer project in the country. Recently, with the signing of the Memorandum of Understanding between the companies, the production line has also become an opportunity for new business. "Today we celebrate not only the inauguration of the Gripen fighter production line, but the success of the collaboration between Saab and Embraer, which grows stronger every day with the common goal of serving our client, the Brazilian Air Force. Since the beginning, Embraer has played a relevant role in the Gripen program, participating, for instance, in the development of the Brazilian version of the twin-seater aircraft. As a natural evolution of this relationship, we hope that soon we can together expand our business into new markets," said Bosco da Costa Junior, President and CEO, Embraer Defence & Security. "The start of operations of the Gripen production line marks our commitment to transfer technology and knowledge to Brazilian industry. Here, we will produce 15 of the 36 aircraft currently contracted to the Brazilian Air Force. The aim is also to produce here any future Gripen orders from Brazil as well as other countries. We want Brazil to become an export hub to Latin America and potentially other regions", said Micael Johansson, President and CEO of Saab. "The start of production of the F-39 Gripen aircraft in Brazil symbolizes the achievement of an ambitious project that translates itself into technology transfer, job creation and the consequent development of Brazil's aerospace sector. Thanks to a solid partnership between the Air Force, Saab, and Embraer, we are now part of the select group of countries that have the capability to build supersonic aircraft. Congratulations to all involved!", said the Brazilian Air Force Commander, Lieutenant-Brigadier Marcelo Kanitz Damasceno. The production line at Embraer receives the aerostructures produced at the Saab plants in Linköping (Sweden) and São Bernardo do Campo (São Paulo State, Brazil). On the assembly line the fighter aircraft will be produced by the joining of these aerostructures, the installation of cabling, equipment of various systems, landing gear, avionics, tactical equipment, canopy, ejection seat and engine. Once a Gripen is completed, functional tests and production flights are carried out to prepare the aircraft for final delivery. The Embraer plant will be responsible for producing 15 Gripen E fighters. Units assembled in Brazil will be delivered from 2025. To acquire the necessary skills for the production of supersonic fighter jets in Brazil, Embraer technicians carried out theoretical and practical training - on-the-job training - at Saab in Linköping. There they worked side by side with Swedish employees to produce the aircraft that have already been shipped to Brazil.   Austro Engine GmbH, a sister company of Diamond Aircraft Industries GmbH, in cooperation with the Austrian Research Promotion Agency (FFG) - owned by the Austrian Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology (BMK) and the Federal Ministry for Digital and Economic Affairs (BMDW), and the Vienna University of Technology have launched a program, supported by Bosch General Aviation Technology GmbH, to develop a bivalent hydrogen engine. The research project is scheduled for completion by end of 2024. There are two different methods for the direct combustion of hydrogen in a piston engine. The initial ignition of the air/hydrogen mixture can be done either by a spark plug or an ignition jet. The advantage of initiating the combustion by a spark plug is a constant 100% hydrogen operation, which in the ideal case was generated 100% regeneratively. However, if the ignition jet method is chosen, there are clear advantages for General Aviation. In the present case, the ignition jet is generated by the existing combustion process with kerosene. The substitution rate of kerosene by hydrogen can be adjusted for combustion stabilization but can also be modulated to 100% kerosene operation due to the current lack of availability of pure hydrogen in some regions of the world. The use of Sustainable Aviation Fuels (SAFs) instead of conventional fossil kerosene for the ignition jet also meets the requirement of 100% substitution of fossil components and has no disadvantages compared to the spark plug-powered hydrogen engine in terms of sustainability. Despite the early development stage of this project, considerable success has already been achieved. A 90% energy substitution rate at part load was achieved, which means a 99% reduction in CO emissions and 89% in CO2 emissions. In addition to the focus on reducing CO and CO2, the already extremely low emissions of unburned hydrocarbons (HCs) at full load (maximum take-off power) were also reduced by 25%. Besides basic research and combustion development, topics such as durability (hydrogen embrittlement) and EASA certification are the focus of the further course of this project. All research has been currently solely done on a test bench. Further information will be released after completion of the three-year program. "Partnerships across industry borders are crucial to achieve sustainability in aviation. At Bosch Aviation Technology we are proud to be technology partner of Austro Engine and the Vienna University of Technology in public funded projects, which integrate hydrogen in an existing engine line-up," commented Christian Grim, General Manager Bosch General Aviation Technology GmbH. "We are convinced that hydrogen will play a major role in regard to sustainable aviation solutions if used with fuel cells or in hydrogen engines. To face decarbonization as a major challenge for General Aviation, it will become increasingly important to search for alternative propulsion systems." Diamond Aircraft and Austro Engine, together with Lufthansa Aviation Training, are also working on Sustainable Aviation Fuels options for the Austro Engine powered aircraft line.   The partnership between Embraer and NetJets began in 2010 when NetJets first signed a purchase agreement for 50 Phenom 300 aircraft, with up to 75 additional options. In 2021, after Embraer successfully delivered over 100 aircraft, the companies signed a continuing deal for up to 100 additional Phenom 300/E jets, in excess of $1.2 billion. With this new agreement, NetJets signifies not only its commitment to creating an enhanced customer experience as the company is averaging over 1,200 worldwide flights per day but also its trust in Embraer's industry-leading portfolio and top-ranked support to deliver the ultimate experience to NetJets customers. "Since 2010, Embraer has enjoyed NetJets' ongoing commitment to our industry-leading aircraft, which is a true testament to the value of our brand and our ability to deliver the ultimate experience in business aviation," said Michael Amalfitano, President and CEO of Embraer Executive Jets. "Our strategic partnership has been an integral part of our business growth, with NetJets taking all aircraft delivery options that have been ordered with Embraer since inception. After building this successful foundation with the Phenom 300 series, it's our pleasure to have now signed this monumental deal for the Praetor 500 midsize jet, and we look forward to an even more exciting future ahead." "We are eager to add the Embraer Praetor 500, one of today's most state-of-the-art business jets, to our midsize fleet," said Doug Henneberry, Executive Vice President of NetJets Aircraft Asset Management. "This historic fleet agreement is another way that we are growing our fleet for the benefit of our loyal customers. By adding up to 250 aircraft to our fleet, we will continue providing NetJets Owners with exceptional service and seamless access to all corners of the globe." The Praetor 500 is the world's most disruptive and technologically advanced midsize business jet, boasting an impressive best-in-class range-enabling U.S. coast-to-coast capability-industry-leading speed, and unparalleled runway performance. In terms of technology, it's the only aircraft in its category with full fly-by-wire flight controls.   AT2 Aerospace's revolutionary hybrid airship is the future of aviation technology. Capable of operating in the most remote and inaccessible locations, this innovative aircraft offers a cost-effective solution for heavy cargo transportation while minimizing environmental and social impact. The Z1's unique Air Cushion Landing System (ACLS) allows the Z1 to land and takeoff from almost any location on the planet. The Z1 utilizes buoyant lift technology delivering exceptional fuel efficiency, minimizing carbon emissions, and ultimately reducing transportation costs. The Z1 will connect emerging economies to global trade networks. The Z1 moves cargo faster than sea and land transportation at a fraction of the cost of existing cargo aircraft, filling a major gap in the global transportation market from a speed vs. cost perspective. The Z1 pen the entire world to commerce, humanitarian aid and exploration with affordable and reliable operations. It is Faster than land and sea. A fraction of existing air cost. Multi-terrain capabilities with air cushion landing system. Buoyant lift technology reduces emission & transportation costs. Simple controls minimize human error. Fuel efficient. Large volume cargo bays, larger payloads. Ability to land in any clear space, even open water. Safer in icing effects. Quiet, ideal for noise sensitive locations.   USA CRASH FOLLOWING IN-FLIGHT FIRE FRESH AIR, INC. CONVAIR CV-440-38, N153JR On March 15, 2012 a Convair CV-440-38, N153JR, operated by Fresh Air, Inc., crashed into a lagoon about 1 mile east of the departure end of runway 10 at Luis Muoz Marn International Airport (SJU), San Juan, Puerto Rico. The two pilots died, and the airplane was destroyed by impact forces. The airplane was operated under the provisions of 14 Code of Federal Regulations (CFR) Part 125(1) as a cargo flight. Visual meteorological conditions prevailed at the time of the accident, and a visual flight rules flight plan was filed. The flight had departed from runway 10 at SJU destined for Princess Juliana International Airport, St. Maarten. Shortly after take-off, the first officer declared an emergency, and then the captain requested a left turn back to SJU and asked the local air traffic controllers if they could see smoke coming from the airplane (the two tower controllers noted in post-accident interviews that they did not see more smoke than usual coming from the airplane). The controllers cleared the flight to land on runway 28, but as the airplane began to align with the runway, it crashed into a nearby lagoon (Laguna La Torrecilla). Radar data shows that the airplane was heading south at an altitude of about 520 ft when it began a descending turn to the right to line up with runway 28. The airplane continued to bank to the right until radar contact was lost. The estimated airspeed at this point was only 88 knots, 9 knots below the published stall speed for level flight and close to the 87-knot air minimum control speed. However, minimum control speeds increase substantially for a turn into the inoperative engine as the accident crew did in the final seconds of the flight. As a result, the airplane was operating close to both stall and controllability limits when radar contact was lost. Pilots flying multiengine aircraft are generally trained to shut down the engine experiencing a problem and feather that propeller; thus, the flight crew likely intended to shut down the right engine (2) by bringing the mixture control lever to the IDLE CUTOFF position and feathering the right propeller, as called out in the Engine Fire In Flight Checklist. This would have left the flight crew with the left engine operative to return to the airport. However, post-accident examinations revealed that the left propeller was found feathered at impact, with the left engine settings consistent with the engine at take-off or climb setting. The right engine settings were generally consistent with the engine being shut down; however, the right propeller's pitch was consistent with a high rotation/take-off power setting. The accident airplane was not equipped with a flight data recorder or a cockpit voice recorder (nor was it required to be so equipped); hence, the investigation was unable to determine at what point in the accident sequence the flight crew shut down the right engine and at what point they feathered the left propeller, or why they would have done so. Post accident examination of the airplane revealed fire and thermal damage to the airframe on the airplane's right wing rear spar, nacelle aft of the power section, and in the vicinity of the junction between the augmenter assemblies and the exhaust muffler assembly. While the investigation was unable to determine the exact location of the ignition source, it appears to have been aft of the engine in the vicinity of the junction between the augmenter assemblies and exhaust muffler assembly. The investigation identified no indication of a fire in the engine proper and no mechanical failures that would have prevented the normal operation of either engine. The safety issues identified in this accident include the following: Inadequate Federal Aviation Administration (FAA) oversight of Part 125 operations. The investigation found that many of the operator's operation and maintenance records were incomplete or nonexistent. The FAA requires annual inspections of each certificated operator, including a review of pilot records, pilot currency, and aircraft maintenance. During the last documented main base inspection, which occurred just over 2 months before the accident, the principal operations inspector (POI) should have discovered the recordkeeping discrepancies and instructed the operator to verify the captain's currency; however, he did not. Likewise, the principal maintenance inspector and the principal avionics inspector should have discovered Fresh Air's deficient aircraft maintenance recordkeeping during the last documented aircraft records inspection, which was conducted 7 days before the accident, or during any of the six inspections conducted in the year before the accident; however, they did not. Further, the National Transportation Safety Board (NTSB) found evidence suggesting that FAA oversight of Part 125 operations was not seen as a priority. Fresh Air's POI told investigators that Part 125 was generally "a GA [general aviation] operation," not an air carrier operation. While most of its flights were relatively close to San Juan, Fresh Air's FAA-approved operations specifications (OpsSpecs) authorized it to operate commercially over the 48 contiguous states, meriting far more scrutiny than "a GA operation." Multiple FAA inspectors failed to perform effective, basic oversight of Fresh Air, possibly due to a belief that Part 125 operations merit less scrutiny than Part 121 and Part 135 operations, and despite the fact that Fresh Air's airplanes fly over populated areas within the national airspace system. Inadequate evaluation of Fresh Air's compliance with FAA-approved procedures. The investigation revealed the FAA's failure to detect and address discrepancies between Fresh Air's approved procedures and its operations, including cargo loading, pilot currency, company recordkeeping, and pilot evaluation. For example, Fresh Air pilots were operating the airplane with the auto feather and antidetonation injection systems off, yet using a higher gross take-off weight than permitted with these systems off, contrary to the FAA-approved airplane flight manual. Because the POI had never directly observed Fresh Air's operation, he was unaware that the airplanes were being operated contrary to the limitations outlined in the airplane flight manual. Evaluation of Part 125 pilots using another operator's OpsSpecs. The investigation revealed confusion among operators and FAA personnel regarding the applicable OpsSpecs that check airmen must use during certain checkrides. While it unlikely affected the captain's capability to handle the accident, his competency check was not necessarily conducted using Fresh Air's OpsSpecs or operations manual. While the investigation could not determine under which company's OpsSpecs and operations manual the captain was evaluated for the Convair, the captain's DC-4 evaluation was conducted using another company's OpsSpecs and operations manual. The NTSB determines that the probable cause of this accident was the flight crew's failure to maintain adequate airspeed after shutting down the right engine due to an in-flight fire in one of the right augmentors. The failure to maintain airspeed resulted in either an aerodynamic stall or a loss of directional control. As a result of this investigation, the NTSB makes three recommendations to the FAA. 1. Title 14 CFR Part 125 applies to large airplanes that are configured for 6,000 lbs or more of payload capacity or 20 or more passengers when these airplanes are being used for any purpose other than common carriage. A carrier becomes a common carrier when it holds itself out to the public, or to a segment of the public, as willing to furnish transportation within the limits of its facilities to any person who wants it. 2. Although the investigation was not able to determine why the crew chose to shut down the engine, they likely suspected an engine fire due to the smoke. What We Found ?We determined that the probable cause of this accident was the flight crew's failure to maintain adequate airspeed after shutting down the right engine due to an in-flight fire in one of the right augmenters. The failure to maintain airspeed resulted in either an aerodynamic stall or a loss of directional control.??  USA, Greenville, KY: The experimental, amateur-built Curtiss JN-4D biplane sustained substantial damage following a loss of engine power and forced landing to open field terrain in Greenville, Kentucky. The two occupants onboard received minor injuries.  USA, Hollywood, FL: A Piper PA-25 Pawnee came down on North Park Road, Hollywood, Florida, and burned out. The pilot was killed. The aircraft departed North Perry Airport, FL (HWO) at 16:24 UTC and circled the airport twice to compete a banner pick-up manoeuvre. It then proceeded to the east. Footage from a news helicopter show the aircraft struggling to maintain altitude. After releasing the banner, the aircraft quickly lost altitude. Control was lost and the aircraft impacted the road, bursting into flames. Slovakia. Novot, Orava region: A Nisus Aero Nisus gyroplane went missing on flight from Topolcany, Slovakia to Bielsko Biala, Poland. The sole person on the board was a Hungarian professional pilot. The wreck was found next day. Heavy fog was reported from the accident area during the time, when the airplane went missing. Spain, Zaragoza Airport: A Spanish AF McDonnell Douglas EF-18M Hornet, assigned to the 15th squadron (Ala 15) of the Spanish Air Force, was destroyed when it crashed during an airshow at Zaragoza Airport (ZAZ/LEZG), Spain. The pilot ejected safely   9 MAY 1912 Lieutenant Commander Charles Samson becomes the first person to fly an aircraft off the deck of a moving ship. He takes off in a Short S.38 from the deck of HMS Hibernia in Weymouth Bay.  In 1911 he was selected as one of the first four Royal Navy officers to receive pilot training, and obtained his Royal Aero Club certificate on 25 April 1911, after only 71 minutes flying time, at a RAeC meeting that also awarded licences to the pioneer naval aviators Wilfred Parke and Arthur Longmore.[3] He completed flying training at Eastchurch before being appointed Officer Commanding Naval Air Station Eastchurch in October 1911. In January 1912 he was promoted to acting Commander. The following April he was appointed Officer Commanding the Naval Flying School at Eastchurch. During 1920 Samson served as Chief Staff Officer in the Coastal Area, and in 1921 became Air Officer Commanding for RAF units in the Mediterranean, based at Malta. In 1922 he was promoted to air commodore and given command of 6 Fighter Group at RAF Kenley (S London). In June 1926 he became Chief Staff Officer of the RAF's Middle East Command, in September 1926 he led a flight from Cairo to Aden: the flight left Cairo on 15 September 1926 and was flown by two Vickers Victoria biplanes and returned to Cairo on 29 September. He later flew an RAF formation of four Fairey III biplanes from Cairo to the Cape of Good Hope.[25] He remained with the Middle East command until August 1927. Samson was placed on the retired list on account of ill health in 1929 and died of heart failure at his home near Salisbury, Wiltshire, on 5 February 1931. He was buried at Putney Vale Cemetery on 10 February.   Van's RV 10 Brakpan to East London Google Banner Ad  |

|

|

|

Copyright © Pilot's Post PTY Ltd

The information, views and opinions by the authors contributing to Pilot's Post are not necessarily those of the editor or other writers at Pilot's Post.