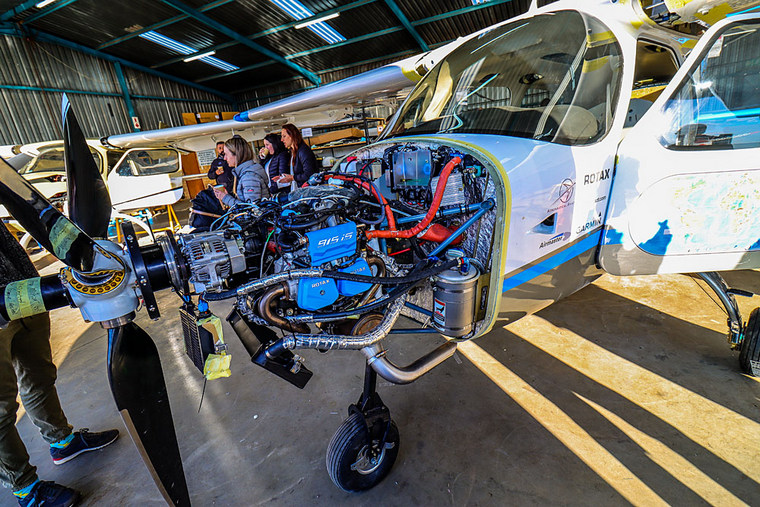

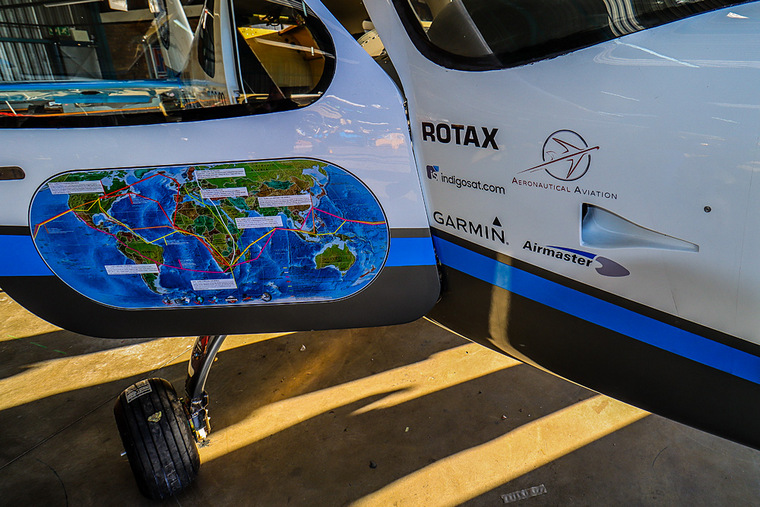

Sling Aircraft - Sling High Wing Oshkosh Farewell BreakfastBy Russell Dixon-PaverGoogle Block Ad Even this early, there was a buzz about, caterers setting up, some Sling aircraft in various stages of final assembly, moved outside to make space for the catering tables, hangars getting a final sweep and the three Sling HW's getting a final wipe-down in preparation for the enthusiastic crowd about to gather for the farewell breakfast. The folks came by air but mainly by road…    The area between the hangars set up for the farewell breakfast, hangar space cleared for serving and breakfast in progress later, while everyone admired the aircraft almost ready for departure and socialised.   Slings in various stages of final assembly moved to make space for catering tables. The Sling 4 evolved into the Sling TSi with the 141hp fuel injected turbocharged Rotax 915 iS engine. The Sling TSi is selling at around 10 kits or built-up aircraft per month. Sling Aircraft have delivered around 900 Sling aircraft in total! Google Block Ad When I went on a factory tour about 10 years ago, they were producing the Sling 2 and the Sling 4 and had around 140 employees at the time. The energy amongst the team was obvious then and now, with around 330 employees it is even more so, and that is really something in a growing business. Mike Blyth, James Pitman and Andrew Pitman make Sling happen with their highly motivated and skilled team! Everyone jumps in to do anything required for success! The High Wing was announced at Oshkosh AirVenture in 2019, and then things were unavoidably delayed by the Covid-19 pandemic and the various worldwide lockdowns and disruptions to supply chains and all aspects of life. As the world started to get back to some semblance of normality, activities could restart in earnest. The HW has also used the Rotax 915 iS and has a composite centre fuselage, from firewall to rear bulkhead, of strong fibreglass & carbon fibre and larger tail surfaces to improve CG range with improved ergonomics. Performance of the HW is very similar to the TSi: 4 seater with a cruise speed of 140-145 knots @ 9000ft. Google Banner Ad Linda Sollars and JP Schulze (“The Candourist”) have been building their new Sling High Wing (HW) aircraft at the Sling Aircraft (formerly known The Airplane Factory) facility at Tedderfield Airpark, South of Johannesburg in South Africa over the last six months from knockdown kits under the “Sling build assist program”. These are the first two production Sling HW machines (effectively the HW production prototypes - Linda's the nose-wheel type and JP's the taildragger variant, following the initial taildragger prototype and then the nose-wheel production prototype.   The hangars where final assembly and finishing work on the three Sling HW aircraft about to head for Oshkosh is under way.   Getting to “nose” you - Linda Sollar's and her beautiful Sling HW.    The Oshkosh HW's - Linda's HW Nosewheel, Sling Aircraft's HW Nosewheel prototype - showing the Rotax 915 iS and constant-speed propeller and JP's HW Taildragger.     ZU-TDR the HW Taildragger prototype/factory demonstrator, static and in action.    Sling HW Taildragger and TSi demonstrator's flypast with a break and then landing during breakfast.    Sling Aircraft HW sporting logos for the upcoming adventure and the world map of long-haul trips already accomplished.    Linda doing some final dusting and views of the beautiful three-colour paint scheme in standard colours of her Sling HW.  Route map on the door of ZU-SHW. The current expedition will roughly follow the route in Orange, but flying around the bulge of West Africa for less overfly permissions requirement and usually better weather over the sea. James spoke about Linda Sollars (who he said was a ”properly curious and inquisitive person"), as the first HW customer, and her husband, Gordon, spending 4 working months out of the last 6 months building her Sling HW. JP was also the first HW Tailwheel customer and he has been building his aircraft at the same time. Their aircraft have been built under the Sling “build assist programme” at the Sling Aircraft factory at Tedderfield Airpark from knockdown kits. James said it has been a privilege working with people of such quality and competence.  James reflecting on the Sling history, introducing the expedition team and giving an overview of the plans for the trip.     Some additional features - adjustable headrest, electrically height adjustable seats and six-position seat rake adjustments and the stunning, professionally finished panel, incorporating features like tyre pressure monitoring. Experimental aircraft - in the US you can work on them yourself, without a license, although this was not an issue for her. Linda looked at all the experimental and certified aircraft as potential replacements, hoping someone would come out with a modern avionics, power plant, capability, range, hauling capacity and especially a high wing. She loved the Sling 2 & 4 and especially the TSi, which Linda really enjoyed flying, but the wings were in the wrong place! She heard a rumour in January 2019 that a Sling HW was on the way and said she has been trying to "flap money in their hands" since that rumour appeared! Linda knew Sling would do it right. Linda wished that the T210 engineers had built it and worked on their aircraft - many things would have been designed differently! The Sling build with the designers and builders has been a great opportunity. They have gone above and beyond and to address her many desires for the Sling HW. Linda expressed appreciation for the opportunity to be a part of this Grand Adventure!   Linda is introduced and then outlines her background and how she came to be the first Sling High Wing customer. James says JP has an A type personality. He grew up in Namibia, moving overseas at 18, and is finding it a spiritual experience to come back to Africa. What he found striking is to see the talent at Sling. The HW build project has been a logistics masterclass. He does not think this could be done in any other country, there is a willingness to work hard, but he got to build his dream airplane with people who are now his friends. He has had the privilege of flying ZU-TDR, the Taildragger prototype, for over 100 hours. Of 126 aircraft types of which he has been PIC flying, he says it is by far the best airplane he has ever flown - and was not paid to say it! Capability, envelope, comfort and feel the special feel and allows continued pursuit of adventures. - Mike Blyth was a pivotal person in his life when he was younger - and it has been hard work and many long hours to get ready, but it wouldn't be an adventure if it wasn't hard! JP has done a great deal of Safari flying in Africa, and also flew a Cessna 210 around the world, made film for Discovery, and will be flying this trip with his friend, William, who is an Englishman living in New Zealand - who is also a filmmaker - and so will be helping to make daily film content of their travels. They will be flying N669JP, the HW Taildragger.    One of the two long-range fuel tanks, which adds 320 litres capacity in total, which will be fitted for the long legs of the trip and JP speaking about his experiences. James said the main difficulty on a long trip is getting along with the other people, not the aeroplane! Flying around the world is quite easy - and getting the right people and mix, is critical. Development prototype taildragger Sling HW was ZU-TDR and ZU-SHW, prototype nose wheel Sling which is doing the trip, is the development HW as there was no production prototype. The first HW machines sold are effectively also the nose wheel production prototypes. The other crews: ZU-SHW - James Pitman with Matt Cohen, who arrived in his yellow FoxBat, has no use of his legs after an accident, but is a competent pilot. SHW can be flown hands-only just like his FoxBat. James says Matt is easy to spend time with.   Matt's Foxbat and the hand controls installed in ZU-SHW, which has yet to have the finishing trimmings installed. James says this is a fantastic team - this will be the first time they have ever done a trip with more than two people in one aeroplane. A bigger team will mean entertainment, more fun and some additional elements of safety by flying together. The Sling HW aeroplanes are much faster so they no longer have to fly at night, so they can now take off in the morning and land before sunset and they are hoping every leg will achieve this. Google Block Ad James gave a special thanks to all the Sling staff, who had put in many extra hours to achieve the deadlines, naming the team leaders of each department. Two Sling Tagati gravel bicycles are also going along for the trip, because adventurers can't be separated from their bicycles for long when they are on the ground, and they provide transport at their many stopovers. Google Block Ad With that, the hangar doors were closed, so the teams could get back to work, finishing the final outstanding items and performing the last tests in preparation for the FAA inspector's imminent arrival.   Sling HW to Oshkosh! Google Banner Ad  |

|

|

|

Copyright © Pilot's Post PTY Ltd

The information, views and opinions by the authors contributing to Pilot's Post are not necessarily those of the editor or other writers at Pilot's Post.