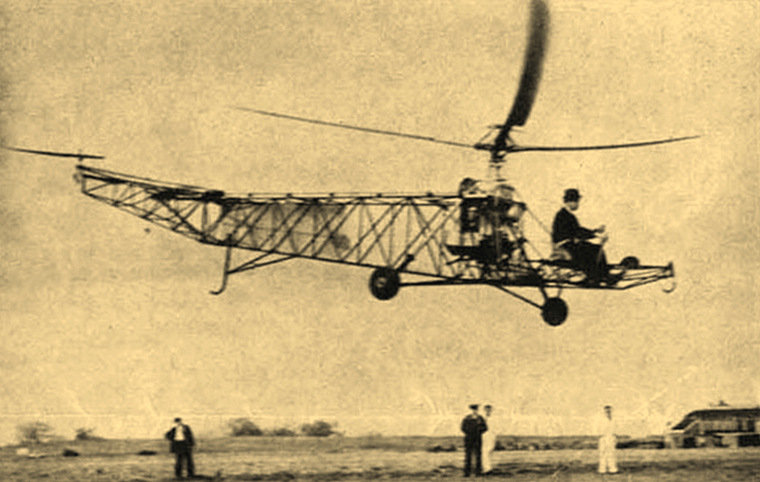

The Fairey Rotodyne 40 passenger VTOL compound gyroplaneBy Willie Bodenstein 2021.02.21 On September 14, 1939, the VS-300, the world's first practical helicopter designed by Igor Sikorsky and built by the Vought-Sikorsky Aircraft, took off for its first flight Stratford, Connecticut in the USA, a division of the United Aircraft Corporation. The VS-300 was the first of its type to incorporate a single main rotor and tail rotor design.   Nine years later, the first series production helicopter, the Mi-1, designed and developed by Mikhail Mil head of the OKB-4 design bureau in Tushino, Russia on 20 September 1948 took flight. Series production started at the Mil Moscow Helicopter Plant in 1955 and by the time production ceased more than 2,500 had left the factory. The UK at that time was slowly recovering from the ravishes of WWII and in the immediate post-war climate, the Royal Air Force (RAF) and Royal Navy elected to procure American-developed helicopters in the form of the Sikorsky R-4 and Sikorsky R-6, known locally as the Hoverfly I and Hoverfly II respectively.  As a legacy of the war, the UK had a multitude of companies involved in the aviation industry, one of which was Fairey Aviation that was intrigued by the potential of rotary-wing aircraft. The company proceeded to develop the Fairey FB-1 Gyrodyne, a unique aircraft in its own right that defined a third type of rotorcraft, including autogyro and helicopter. In 1948, the FB-1, the first prototype, proved its potential during test flights when it achieved a world airspeed record, having attaining a recorded speed of 124.3 mph (200.0 km/h). The second FB-1 prototype, the Jet Gyrodyne, was modified to investigate a tip-jet driven rotor with propulsion provided by propellers mounted at the tip of each stub wing.  Photo Johannes Thinesen / commons.wikimedia.org In 1951, British European Airways (BEA) formulated a requirement for a passenger-carrying rotorcraft able to carry a minimum of 30 passengers on journeys between major cities. Both civil and government bodies had predicted the requirement for such rotorcraft. Subsequently, the UK Ministry of Supply proceeded to sponsor a series of design studies to be conducted in support of the BEA requirement. The BEA Bus requirement was met with a variety of futuristic proposals, among these one from Fairey who submitted its Rotodyne. The firm made its first submission to the Ministry on 26 January 1949. The Rotodyne featured a tip-jet-powered rotor that burned a mixture of fuel and compressed air bled from two wing-mounted Napier Eland turboprops. The rotor was driven for vertical take-offs, landings and hovering, as well as low-speed translational flight, but autorotated during cruise flight with all engine power applied to two propellers. In October 1950, an initial contract for the development of a 16,000 lb, four-bladed rotorcraft was awarded. The Fairey design, which was considerably revised over the years, received government funding to support its development and in April 1953, the Ministry of Supply contracted for the building of a single prototype of the Rotodyne Y, powered by a pair of Eland N.El.3 engines furnished with auxiliary compressors and a large-section four-blade main rotor, with a projected all-up weight of 33,000 lb. The Rotodyne would have been the largest transport helicopter of its day, seating a maximum of 40 to 50 passengers, while possessing a cruise speed of 150 mph and a range of 250 nautical miles.  While construction of the first prototype was underway, funding for the programme reached a crisis and cuts in defence spending led the Ministry of Defence to withdraw its support. However, prospects for the Rotodyne appeared positive. BEA was monitoring the progress of the programme with interest. The American company Kaman Helicopters also showed strong interest in the project and was known to have studied it closely as the firm considered the potential for licensed production of the Rotodyne for both civil and military customers. In 1956, the military's announcement that it had no further interest in the further development of the Rotodyne left the project completely reliant upon civil budgets. One prototype was built and on 6 November 1957, the prototype performed its maiden flight, and on 10 April 1958, the Rotodyne achieved its first successful transition from vertical to horizontal and then back into vertical flight. The Rotodyne had a large, four-bladed rotor and two Napier Eland N.E.L.3 turboprops, one mounted under each of the fixed wings. The rotor blades were a symmetrical aerofoil around a load-bearing spar. The aerofoil was made of steel and light alloy because of centre of gravity concerns. The compressed air was channelled through three steel tubes within the blade. For take-off and landing, the rotor was driven by tip-jets. The air was produced by compressors driven through a clutch off the main engines. This was fed through ducting in the leading edge of the wings and up to the rotor head.  Photo Les Chatfield / commons.wikimedia.org Each engine supplied air for a pair of opposite rotors; the compressed air was mixed with fuel and burned. As a torqueless rotor system, no anti-torque correction system was required, though propeller pitch was controlled by the rudder pedals for low-speed yaw control. The propellers provided thrust for translational flight while the rotor autorotated. The cockpit controls included a cyclic and collective pitch lever, as in a conventional helicopter. On 5 January 1959, the Rotodyne set a world speed record in the convertiplane category, at 190.9 mph (307.2 km/h), over a 60-mile (100 km) closed circuit. As well as being fast, the rotorcraft had a safety feature: it could hover with one engine shut down with its propeller feathered and the prototype demonstrated several landings as an autogyro. The prototype was demonstrated several times at the Farnborough and Paris air shows, regularly amazing onlookers. In one instance, it even lifted a 100 ft girder bridge. Although the Rotodyne was promising in concept and successful in trials, the programme was eventually cancelled. The termination has been attributed to the type failing to attract any commercial orders: - this was in part due to concerns over the high levels of rotor tip jet noise generated in flight. Politics had also played a role in the lack of orders which ultimately doomed the project. www.youtube.com/channel/UCCuRVZAGodT6sztTeXBGeMw and subscribe to our YouTube channel  |

|

|

|

Copyright © Pilot's Post PTY Ltd

The information, views and opinions by the authors contributing to Pilot's Post are not necessarily those of the editor or other writers at Pilot's Post.